The Surprising Reason Ford Went With LFP Batteries For Its $30,000 EV Truck

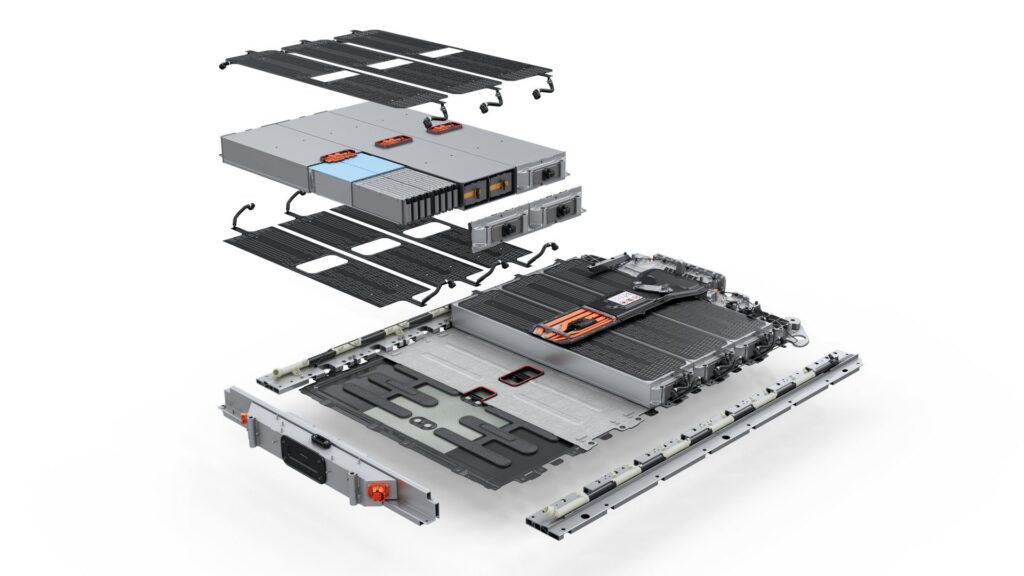

Ford is reinventing the way it designs and makes cars with its next-generation Universal Electric Vehicle (UEV) Platform. That also requires overhauling the battery powers everything.

Deciding what battery chemistry to use and how was probably the most nerve-racking decision of the entire project, Alan Clarke, a 12-year Tesla veteran and the executive director of Advanced EV Development at Ford, told me and Patrick George during an interview on this week’s Plugged-In Podcast.

“The team was the smallest when we made that decision three years ago,” he said. “And the risk, the capital risk, was extremely high, because we pretty much said, whatever we decide, we’re going to build a battery factory to make these batteries. And that’s a big decision.”

After considering many different cell types and chemistries, poring over mass and cost data, and designing many packs from start to finish, Clarke’s team landed on lithium iron phosphate (LFP) cells for the first vehicle to use the new architecture, a $30,000 midsize pickup truck scheduled for production next year.

They will take on a prismatic shape—a box instead of the cylindrical cells that Tesla favors or the slim, flexible pouches that went into the F-150 Lightning and Mustang Mach-E. Ford plans to crank out the cells at a new plant in Michigan, using technology licensed from the world’s biggest battery maker, China’s CATL.

Ford’s affordable electric truck goes into production in 2027 with a streamlined silhouette.

Photo by: Ford

The rationale for using LFP seems self-evident if you’ve been following the battery space. Highly durable and far cheaper than the high-nickel cells that have historically dominated passenger vehicles, the chemistry has quickly gained popularity as the workhorse of the EV world. Globally, LFP battery packs cost $81 per kilowatt-hour at the end of 2025, compared with $128/kWh for nickel manganese cobalt packs, according to BloombergNEF. That cost advantage helped propel LFP to become the dominant battery chemistry globally for the first time ever in 2025.

Cost is certainly central to the equation for Ford. It wants to launch a $30,000 EV—something very few automakers have done in the U.S.—and it wants to make that vehicle both desirable and profitable. “We get the lowest cost for the first product with this chemistry,” Clarke said.

But there was another reason behind the decision. A drawback of LFP batteries is that they’re heavier and pack less energy than high-nickel cells. By designing the UEV platform to work well with LFP cells, Clarke’s team solved “the hardest thing first,” he said.

“We assumed it would be the least energy dense chemistry that we’d put into the platform. So it would take up the most amount of space and be the heaviest. And so, at the end of the day, it should in theory be the hardest thing that we ever designed,” he said.

This approach means that future UEV products that use higher-performance chemistries should get even longer range than the debut truck, he said. On the other hand, had Ford designed the vehicle to use energy-dense NMC cells, it might not have the packaging space to accommodate a cheaper LFP variant down the line with satisfactory specs.

As for what those specs will be, we have more questions than answers, even after Ford’s media blitz this week. The automaker has said it’s ruthlessly focused on aerodynamics for the midsize truck, and that it wants to deliver good range without a large, expensive battery pack. It has touted a new “assembly tree” that will replace the assembly line Ford pioneered a century ago. And it has revealed a teaser image that depicts a more streamlined and less boxy pickup than your typical F-150 or Maverick.

But concrete details about the vehicle or how much range it will offer are scant for now. What’s clear is this: Given Ford’s cancellation of EV projects like the F-150 Lightning and its resulting $19.5 billion writedown, there’s a lot riding on the UEV products hitting the mark.

Contact the author: Tim.Levin@InsideEVs.com